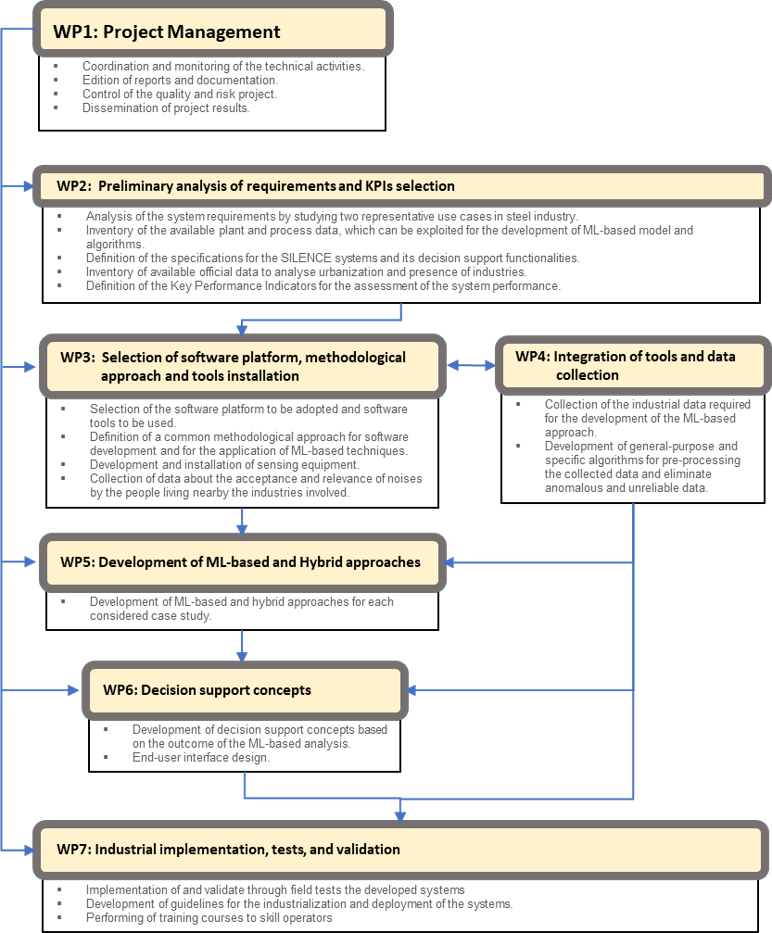

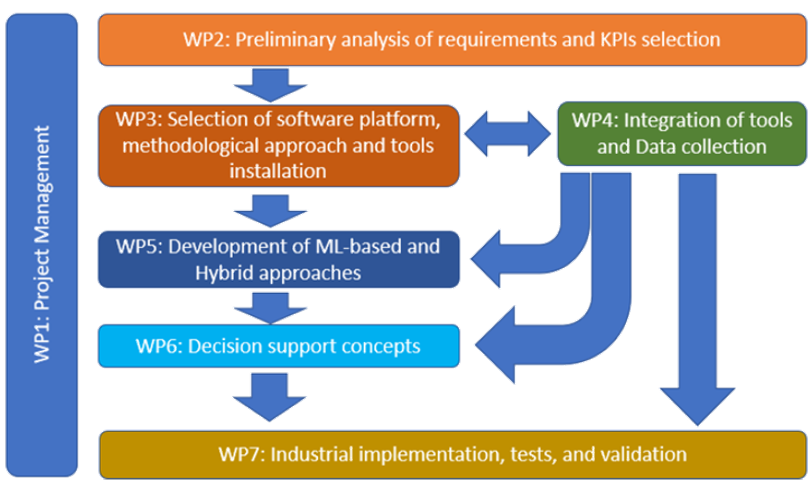

The SILENT consortium is coordinated by CSM following the guidelines of the RFCS program and it has defined a clear-cut assignment of responsibilities and tasks to be performed by the partners. The project is divided into 7 complementary and interrelated work packages (WPs) as illustrated below:

WP1 - Project Coordination and Management

Objective:

Ensure effective coordination, quality control, risk management, and

dissemination.

- Coordinate project meetings and monitor progress.

- Prepare reports and deliverables with input from all partners.

- Manage risks and ensure quality standards.

- Disseminate results across the European and international steel sector, respecting confidentiality and IPR.

Activities and results:

During the 'Digital-4-Environment' workshop (Feb. 2024), a poster was presented

WP2 - System Requirements and Data Inventory

Objective:

Define system requirements and data sources through industrial use cases

and social analysis.

- Defined system requirements for the plants of both the industrial partners.

- Identified the most relevant process data, secured access to meteorological data (through on-site stations and web sites) and gathered Historical and current acoustic data from communities near the plants.

- Defined Key Performance Indicators (KPIs) to evaluate system performance and noise reduction effectiveness.

- Collected stakeholder feedback through interviews and questionnaires with workers, management, and local residents.

WP3 - Platform Design and Sensor Deployment

Objective:

Define the software platform, development methodology, and deploy

acoustic monitoring systems.

- Defined the methodological framework for data acquisition, management, and software development with ML integration for a Decision Support System.

- Selected software platforms, programming tools, and databases compatible with industrial IT for algorithm development and ML/statistical analysis.

- Industrial partners and consortium chose the type and location of sound level sensors for required measurements.

- Analysis of complaints and official data revealed significant noise issues near APERAM, with direct questionnaires as the most reliable source.

WP4 - Data Collection and Pre-processing

Objective:

Collect industrial and acoustic data and develop pre-processing

algorithms for ML applications.

- Hypothesized a possible acoustic signal and development of the calculations to identify the threshold for impulsive phenomena and a neural models that will be used to predict noise levels

- The collection of weather and acoustic data has started (FENO case)

WP5 - Development of ML-Based Models

Objective:

Develop machine learning and hybrid models tailored to each industrial

case study.

- The development of ML and hybrid models for noise prediction is delayed due to insufficient data from industrial servers.

WP6 - Decision Support System and User Interface

Objective:

Develop decision support tools and design an intuitive user interface.

- The two industrial partners have defined the first version of their DSSs with a first draft of the activities and countermeasures to be adopted in case of exceeding the tolerable thresholds.

WP7 - System Validation, Guidelines and Training

Objective:

Test the SILENCE system in real industrial settings, assess results, and

support future deployment.

- Implement and validate the DSS at FENO and APERAM through field tests and operator feedback.

- Compare pre- and post-implementation acoustic data to evaluate system effectiveness.

- Develop industrialization guidelines and assess economic feasibility.

- Organize training modules for operators and evaluate social impact through surveys.